Équipement de concassage

Pyrophyllite is a kind of clay minerals, smooth and soft. The newly explored pyrophyllite mine has storage around 3 million tons, which the aluminum content occupies 30-39%, Fe2O3+TI2O<0.2%. It can be used as moulds of artificial diamond, porcelain, fireproofing material, glass fibre and carving stone. It is widely used in such industries as porcelain, metallurgy, construction material, chemistry, etc.

| Fineness | Applications | Recommended Equipment |

| Around 200 meshes | Used in porcelain, papermaking, rubber products, cosmetics and pesticide carrier. The new applications of pyrophyllite are coatings, wall plate materials and white cement production materials. | MTM,MTW,LM |

| 3 mm | Used to produce fireproofing materials and fireproofing bricks. | PC Series Grinder |

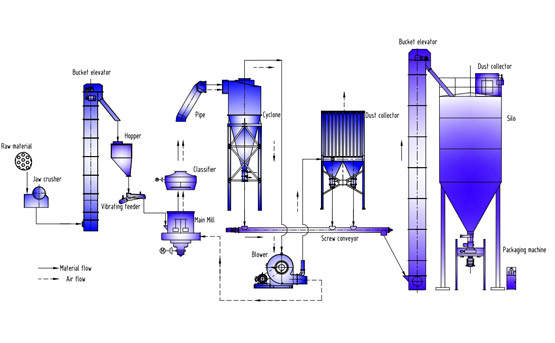

1.Crushing Stage: Big blocks would be crushed into materials within 15mm-50mm--- the feeding size of grinders.

2.Grinding Stage:The small qualified pieces would be evenly sent, by conveyor and feeder, into the grinding cavity where the materials would be ground into powder.

3.Grading Stage:The ground material with air flow would be graded by powder separator. After that, the unqualified powder would be sent back to the grinding cavity for another grind.

4.Powder Collecting Stage: With air flow, powder meeting the fineness standard enters into the powder collecting system along the pipe. The finished powder products are sent to finished product warehouse by conveyor and packed by powder filling tanker and automatic pack machine.

Coarse Powder Technology:

1.Crushing Stage:Big blocks would be crushed into materials within 15mm-50mm--- the feeding size of grinders.

2.Powder Processing Stage: The small qualified pieces would be evenly sent, by conveyor and feeder, into the grinding cavity where the materials would be ground into powder.