Équipement de concassage

Talc, also known as liquid stone and cold stone, is a common silicate. The Moh's hardness is 1 and it is the existing softest mineral which can replace chalk to mark. Scratching it by nails, we can leave a mark on it. Talc is lumplish, leaf-like and radial. Usually, its color includes white and greywhite and sometimes it can present other colors because of the impurities.

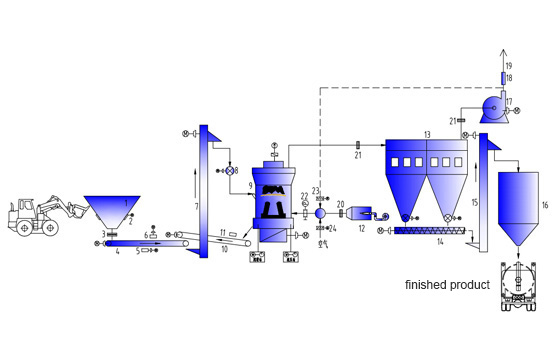

1.Crushing Stage:Big blocks would be crushed into materials within 15mm-50mm--- the feeding size of grinders.

2.Grinding Stage:The small qualified pieces would be evenly sent, by conveyor and feeder, into the grinding cavity where the materials would be ground into powder.

3.Grading Stage:The ground material with air flow would be graded by powder separator. After that, the unqualified powder would be sent back to the grinding cavity for another grind.

4.Powder Collecting Stage: With air flow, powder meeting the fineness standard enters into the powder collecting system along the pipe. The finished powder products are sent to finished product warehouse by conveyor and packed by powder filling tanker and automatic pack machine.